Cobots: How to Meet Your Safety Needs

Isaac Asimov’s Three Laws of Robotics

First Law - A robot may not injure a human being or, through inaction, allow a human being to come to harm.

Second Law - A robot must obey the orders given it by human beings except where such orders would conflict with the First Law.

Third Law - A robot must protect its own existence as long as such protection does not conflict with the First or Second Law.

Cobots Are Not Robots

No longer the work of science fiction, robotics has evolved several times since Asimov first contrived the three laws of robotics in his work ‘I, Robot’. Our concerns have remained the same; however, how can we feel safe with our new automated co-workers?

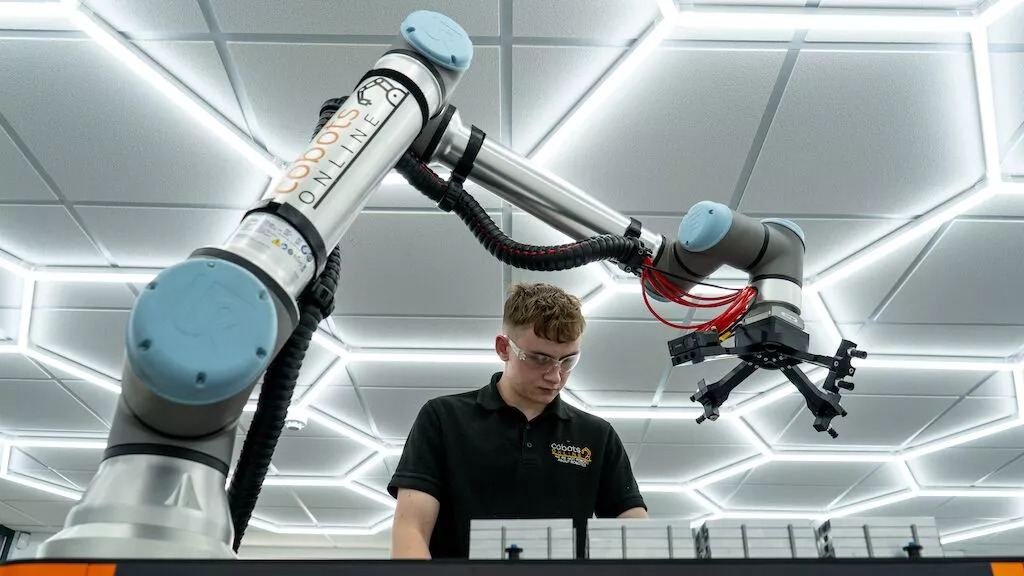

Collaborative robots, or cobots as they are otherwise known, are robots designed for direct human-robot interaction. Like industrial robots, they conduct repetitive, error-prone tasks; however, they operate in more of an assistant role in creating a safer and more efficient workplace.

Cobots are more compact than conventional robots; cobots generally have lightweight frames with soft, rounded edges and minimised pinch points. Thanks to force feedback, low-inertia servo motors, elastic actuators and collision detection technology limit their power and force capabilities to levels suitable for contact with a human body.

While a cobot itself is inherently safe, a cobot does not usually operate on its own; it will require end effectors or grippers, it will typically work in conjunction with other equipment, and most importantly, it will be working with a workpiece. All these factors, when combined, can create hazards and risks to humans.

What Safety Standards Do You Need to Consider?

ISO 10218-1, ISO 10218-2 and technical specification ISO TS-15066 define the safety functions and performance of the collaborative robot.

The robot system described in ISO 10218-2 consists of a robot arm, its end effector, an additional linear axis, connected machinery and processes, devices, and sensors that may be required to assist the robot in completing its tasks.

Under TS-15066, the force and speed monitoring of the cobot is set based on application data, human contact area, and workspace hazards. We define human contact in two types: transient and quasi-static. The former refers to contact that is non-clamping, whereas the latter involves situations that can cause the clamping of a body part.

The design principles contained within ISO TS15066 supplement ISO 10218/2 and create a basis for designers to follow in creating collaborative applications. It is essential to list and map out all additional equipment in the complete collaborative automation project. Manufacturers should evaluate each device for potential hazards and identify safety sensors to use that prevent human and equipment damage. In addition, the collaborative workspace must be clearly marked.

The following are examples of non-collaborative safety-rated equipment that can be part of the workspace requiring safety devices:

- Material handling

- Tooling

- Grippers/actuators

- Machines

Safety And Machine Tending

Machine tending is the most common application for collaborative robots, as it is easy to install, has a high and fast return on investment, and its flexible manufacturing capabilities. Machine tending applications can also be misleading in appearing safe when they are not.

At Cobots Online, we were aware that many end-users had implemented cobot based machine tending without prior knowledge of the standards and legal requirements to ensure the cell is safe. This lack of awareness leads to built-in hazards in the cell, and the potential for accidents is significantly high. With the fines levied by the HSE for workplace injuries getting ever higher, users of collaborative applications must design, build and commission within the guidance of these standards.

CoboTend by Cobots Online is a self-contained mobile machine tending unit which incorporates several programmable safety features, such as safety laser scanners, which permit the end-user to re-configure the cell each time the application is changed.

Risk Assessment

When integrating a robot or cobot into a system, cobot users must conduct a risk assessment of the entire system, complete with end effectors/grippers and other ancillary equipment. The resulting control measures implemented to reduce the risks will safeguard a safe, collaborative operation. Users must conduct a full risk assessment regardless of the safety features built into the robot arm. In addition, each time you re-task your cobot to do a different job or process, you must undertake a new risk assessment and additional control measures introduced to mitigate any new risks identified.

Cobots Online can provide guidance; however, as with all new applications in a manufacturing environment, the end-user should always conduct a final risk assessment. Once completed, however, you will have just installed your newest team member, which significantly reduces workplace injury, does not require downtime and brings an unbeatable level of consistency to production. You will question how you ever lived without it!

Conclusion: Safety First!

Isaac Asimov may have had more conventional AI robots in mind, but his safety rules still apply. At Cobots Online, we care about keeping your workplace safe, as safe as our manufacturing factory! We will not tell you cobots are a ‘safe out of the box’ option. Instead, we will help you through every step to getting your cobots up and running in no time.

To discuss your cobot needs or any questions regarding cobot safety, please get in touch here.